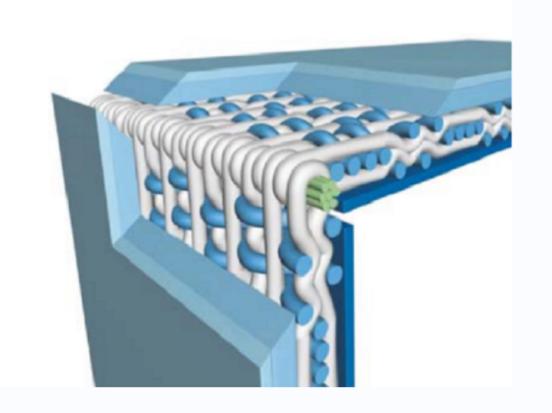

The selection and design of the base mesh yarn are based on the running conditions of the paper machine, which makes the ratio of fiber and bottom mesh more reasonable

In the process of base mesh weaving and heat setting, it is necessary to ensure flatness of the surface and seam joint, especially to ensure that the weft yarn at the seam joint does not appear bending and inclination

Unique production process ensure the hardness and stiffness of the seam joint, to avoid seam joint gap and mark on paper sheet during felt running under tension.

The seam is cut by an experienced operator to ensure the seam straight.

When the seam cutting, technician must master a certain angle of inclination to form a long fiber edge that perfectly covers the short fiber edge.

The seams must be treated with special soluble short fibers to ensure that the velvet at the seams will not spread

Base mesh heat setting, needle punched, felt heat setting and seam treatment must be separated for 48 hours before the next step, and each step is based on sufficient tension, the purpose is to avoid excessive gaps at the seams.

More advanced needling technology, select the most suitable needle type and match the corresponding needling frequency, to ensure that the yarns and fibers at the seam joint are not damaged.

can not be empty

can not be empty